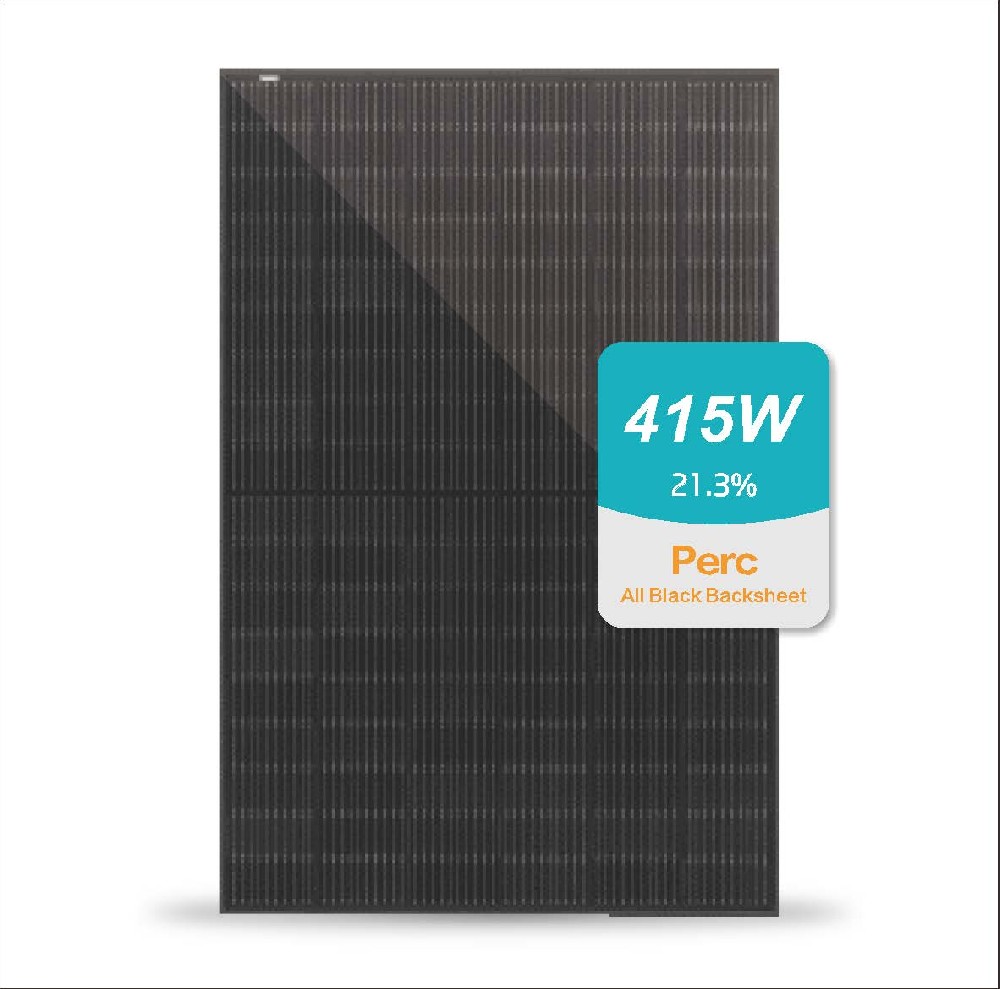

MG10 Perc All Black glass backsheet 108 Half Cells 415W 410W 400Wp 390Watt single glass Solar Module

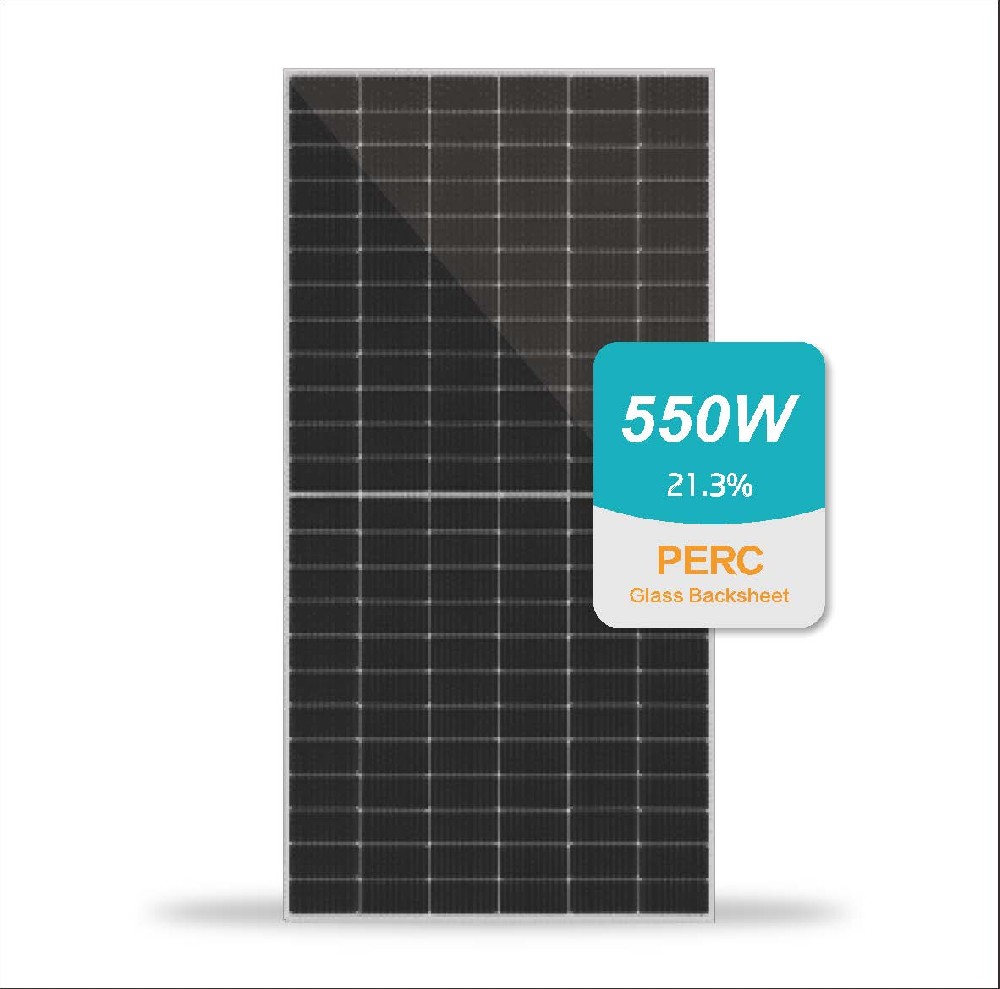

MG10 Perc monocrystalline all black glass backsheet 390w-415w photovoltaic solar module. The new series integrates 182mm silicon wafers, with perc, multi-busbar cell technology and high-density encapsulation. The maximum power output on the front side of the three formats, 108 / 120 / 144 half cells, maximum output power reach 560Wp.

Electrical Specification

| Maximum Power (Pmax/W) | 390 | 395 | 400 | 405 | 410 |

| Maximum Power Voltage (Vmp/V) | 30.64 | 30.84 | 31.01 | 31.21 | 31.45 |

| Maximum Power Current (Imp/A) | 12.73 | 12.81 | 12.90 | 12.98 | 13.04 |

| Open Circuit Voltage (Voc/V) | 36.85 | 36.98 | 37.07 | 37.23 | 37.32 |

| Short Circuit Current (Isc/A) | 13.61 | 13.70 | 13.79 | 13.87 | 13.95 |

| Module Efficiency (%) | 20.0 | 20.2 | 21.5 | 21.8 | 22.0 |

| Power Output Tolerance (W) | 0~+5W |

| Temperature Coefficient of Isc | +0.045%/°C |

| Temperature Coefficient of Voc | -0.275%/°C |

| Temperature Coefficient of Pmax | -0.35%/°C |

Certifications

All of MogenSolar's products have been certified by professional third-party testing bodies around the world, and the testing conditions are complex and diverse, from ordinary installation conditions to various extreme weather conditions, natural environments. We pursue the ultimate in quality and provide the best guarantee for customers' assets and profits.

ISO 9001: 2015: ISO Quality Management System

ISO 14001: 2015: ISO Environment Management System

ISO 45001: 2018: Occupational Health and Safety

CE & EU declaration of conformity

IEC 61215 / IEC 61730 Anti-PID Test for Photovoltaic Module

IEC 61701 Salt Mist Corrosion Test for Photovoltaic Module

IEC 60068-2-68 Dust and Sand Test for Photovoltaic Module

UL1703 / UL 61730 – PV Module Safety Standards by UL / CSA / INTERTEK

Italian First-Class Report on Fire Prevention

INMETRO Ex Tariff for Brazil

MCS / JEPC & JET / CEC(Clean Energy Council) approved PV modules / FIDE / CB / DEWA / RETIE

What's the advantage of PERC solar panels?

Understanding how PERC solar panel technology works, is key to understanding the pros and cons of different applications. In this section, we round up the major pros and cons of PERC solar panel technology and highlight some of its best features.

Pros

Up to 1% more efficiency than traditional c-Si solar panels.

Reduced heating absorption, allowing PV systems to perform better at high temperatures.

Operation on a wider light spectrum.

Better usage of the available space.

Cost-effective technology.

Prices for PERC solar panels will get reduced as the technology becomes more popular.

PERC solar cells can be combined with IBC or Bifacial technology.

Cons

Relatively larger cost than traditional technologies.

Light-Induced Degradation (LID) and Potential-Induced Degradation (PID) were a problem in the past for the technology. (Not anymore, since most manufacturers overcame these barriers).

Passivated Emitter and Rear Contact (PERC) technology is an excellent improvement that allows solar cells to achieve higher efficiencies. While this technology presented several cons in the past like LID and PID, manufacturers found ways to solve this, resulting in high-efficiency PERC solar panels without the cons of the technology in the 80s.

Since manufacturers can either design regular PERC solar panels or combine them with IBC or bifacial technology, the range of applications for this technology is quite broad. PERC solar panel technology can be used on residential, commercial, and industrial applications (including utility-scale applications).

For residential purposes, PERC solar panels can be used as regular rooftop photovoltaics, EV solar roof chargers, and solar sheds. For commercial and industrial applications, this technology can be used for ground photovoltaic power stations (especially when combined with bifacial technology), Building Integrated Photovoltaics (BIPV), water surface power stations, and much more.

The use of this technology is quite convenient for the solar industry in general. With the rise of PERC solar panels, homeowners and utilities can benefit by using less space, fewer installation components, and using PV modules with higher performance and an infinity of applications.